Boost Efficiency & Cut Costs: The Ultimate Guide to Industrial Magnetic Plastic Door Curtains

In today's competitive industrial landscape, every operational efficiency translates into a stronger bottom line. Warehouse managers, procurement specialists, and factory owners are constantly seeking solutions that reduce overhead, improve safety, and enhance productivity. One of the most impactful yet often overlooked solutions is the industrial magnetic plastic door curtain.

These aren't your standard strip doors. By integrating a self-closing magnetic seal, they create a superior barrier that delivers significant returns on investment. This definitive guide explores how these systems work, their financial benefits, and how to select the perfect solution for your facility, whether you manage a cold storage warehouse, a food processing plant, or a high-traffic logistics hub.

👉 Get Your Factory-Direct Quote Now

What Are Magnetic PVC Strip Curtains and How Do They Work?

At its core, a magnetic PVC strip curtain is an advanced barrier system designed for doorways in commercial and industrial environments. It consists of overlapping strips of flexible polyvinyl chloride (PVC) that part easily for traffic and then fall back into place. The key innovation is the integration of magnets along the edges of the strips, creating a hands-free, self-closing door. 👉Request a Special Quotation Now

The Core Difference: Magnetic vs. Standard Strip Doors

While both systems use PVC strips to create a barrier, their performance differs significantly.

- Standard Strip Doors: Rely on gravity and the weight of the strips to fall back into place. This often leaves gaps, especially in high-traffic areas or where air pressure differentials exist. These gaps compromise the integrity of the environmental seal.

- Magnetic Strip Doors: The embedded magnets along the edges of each strip actively pull the strips together, creating a complete, gap-free seal after every passage. This self-closing magnetic PVC strip curtain ensures the barrier is almost always intact, dramatically improving its effectiveness.

👉 Get Your Factory-Direct Quote Now

The Science of the Self-Closing Magnetic Seal

The efficiency of a magnetic curtain lies in the calibrated magnetic force. The magnets are strong enough to create a tight seal that contains air, dust, and pests but are precisely engineered to release with minimal pressure. This allows for seamless, hands-free passage for personnel, hand trucks, and even heavy machinery like forklifts. As soon as the traffic passes, the magnetic attraction instantly reseals the opening, minimizing energy loss and contaminant entry.

👉 Get Your Factory-Direct Quote Now

Understanding Key Components: Strips, Magnets, and Mounting Hardware

A complete system is more than just the plastic. Understanding each component is crucial for making an informed purchasing decision.

| Component | Description | Key Considerations for B2B Buyers |

|---|---|---|

| PVC Strips | The main body of the curtain, made from durable, flexible PVC. Available in various thicknesses, widths, and material grades (e.g., standard, polar/low-temp). | Transparency for safety, thickness for durability, and material grade appropriate for the operating temperature. |

| Embedded Magnets | Industrial-grade magnets are welded into waterproof pockets along the vertical edges of the strips. | Magnetic strength must be sufficient for a tight seal but allow easy passage. The waterproof seal is critical for longevity, especially in wash-down environments. |

| Mounting Hardware | Typically made of galvanized steel or stainless steel, this hardware secures the strips to the top of the door frame. Common types include wall-mount and in-jamb mount. | A magnetic PVC strip curtain with mounting hardware should be corrosion-resistant and engineered for fast installation and easy replacement of individual strips. |

👉 Get a Custom Quotation Now

Unlocking ROI: The Financial Case for Magnetic Door Curtains

An investment in high-quality magnetic door curtains pays for itself through measurable operational savings and quality improvements. The financial benefits extend far beyond the initial purchase price.

👉 Get Your Factory-Direct Quote Now

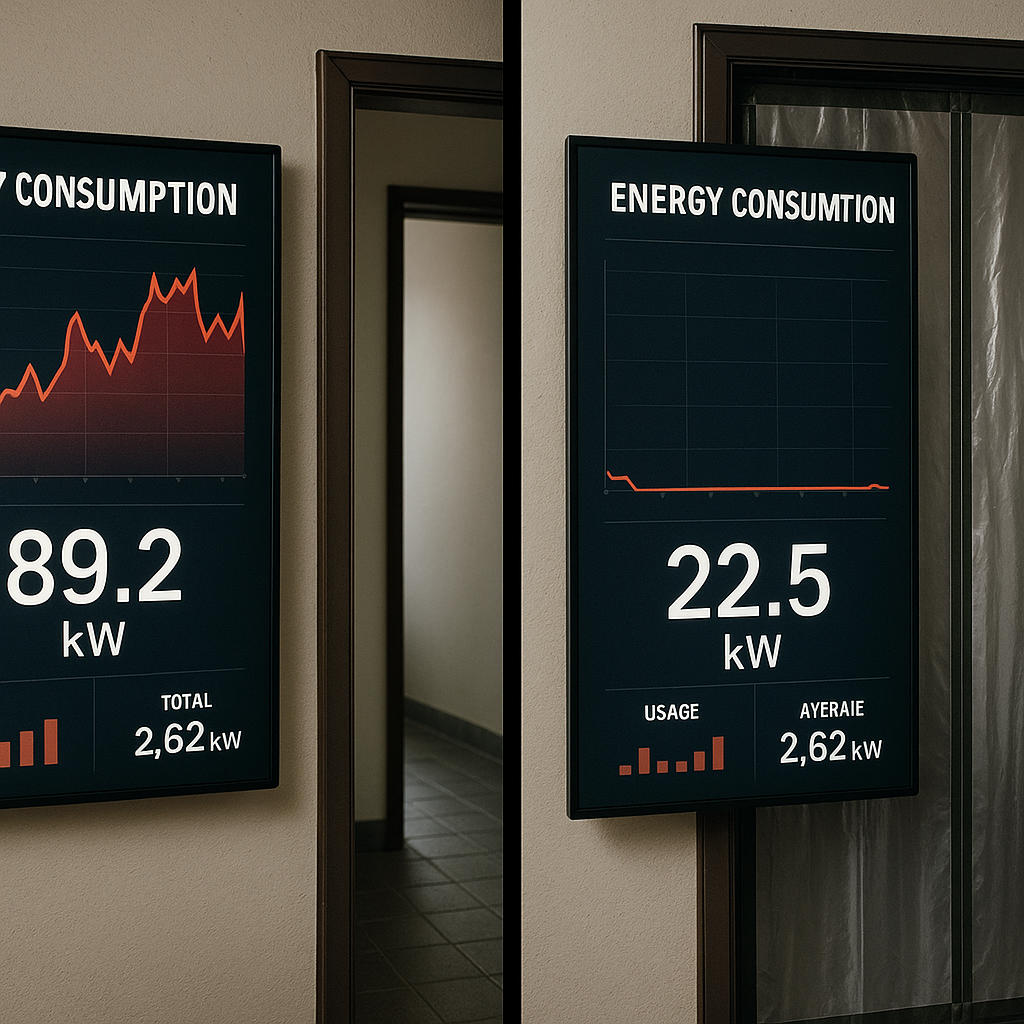

Calculating Energy Savings with Energy-Efficient Magnetic PVC Strip Doors

In a refrigerated or freezer environment, an unmanaged doorway can be responsible for up to 50% of the total refrigeration load. A properly sealed magnetic curtain can cut that loss by over 75%, leading to substantial reductions in electricity consumption and HVAC system strain.

These energy-saving magnetic plastic curtains for industrial use lower utility bills month after month, delivering a rapid payback period.

How Reduced Contamination Impacts Product Spoilage and Quality Control

For industries like food processing, pharmaceuticals, and electronics manufacturing, contamination is a direct threat to profitability. Magnetic curtains provide a robust barrier against:

- Dust and airborne particulates

- Insects and other pests

- Humidity and external weather conditions

By creating a more stable and cleaner internal environment, these curtains help reduce product spoilage, improve compliance with quality standards, and minimize costly production-line rejects. This is a critical function of magnetic plastic door curtains for pest control.

👉 Get Your Factory-Direct Quote Now

Analyzing Long-Term Value: Durability vs. Initial Investment

While the upfront cost of a magnetic system may be higher than a standard hook-on door, its long-term value is far superior. The robust construction of heavy-duty magnetic PVC curtains and the reduced wear on HVAC systems lead to a lower total cost of ownership. The consistent seal prevents the constant energy loss associated with gapping standard strips, meaning the initial investment is quickly recouped through operational savings.

Material Deep Dive: Choosing the Right PVC Grade for Your Application

Selecting the correct material is paramount to the performance and longevity of your industrial curtain. The choice depends entirely on the operating environment.

👉 Get Your Factory-Direct Quote Now

Standard vs. Low-Temp (Polar) PVC: What's the Difference?

- Standard Grade PVC: Ideal for ambient temperatures ranging from 0°F to 150°F (-18°C to 66°C). It maintains flexibility and durability in most warehouse, manufacturing, and workshop environments.

- Low-Temp (Polar) Grade PVC: Specially formulated to remain flexible in cold conditions, rated for temperatures from -40°F to 140°F (-40°C to 60°C). Standard PVC will become brittle and crack in freezers, making magnetic PVC freezer room curtains made from Polar grade essential for any sub-zero application.

👉 Get Your Factory-Direct Quote Now

The Importance of Strip Thickness and Overlap for Heavy Industrial Use

For environments with heavy forklift or pallet jack traffic, durability is key.

- Thickness: Thicker strips (e.g., .120" or .160") provide greater resistance to tearing and abrasion.

- Overlap: A higher percentage of overlap (e.g., 50% to 100%) creates a more robust barrier and ensures a better seal, especially on large or high-wind doorways.

Choosing a durable magnetic plastic strip for high-traffic doors with appropriate thickness and overlap is critical for long-term performance.

👉 Get Your Factory-Direct Quote Now

Technical Specifications Overview (EAV Model)

| Entity | Attribute | Value |

|---|---|---|

| Material | Grade | Standard, Polar (Low-Temp), Ribbed, Anti-Static, Welding Grade |

| Thickness | .080" (2mm), .120" (3mm), .160" (4mm) | |

| Width | 8" (200mm), 12" (300mm), 16" (400mm) | |

| Performance | Temperature Range (Standard) | 0°F to 150°F / -18°C to 66°C |

| Temperature Range (Polar) | -40°F to 140°F / -40°C to 60°C | |

| UV Resistance | Available with UV inhibitors for outdoor applications | |

| Construction | Magnet Type | Neodymium or Ferrite, RF-welded into waterproof seams |

| Hardware Material | Galvanized Steel, Stainless Steel (304 Grade) | |

| Overlap Options | 50% (Standard), 67% (Heavy Duty), 100% (Extra Heavy Duty) | |

| Compliance | Certifications | REACH Compliant, Phthalate-Free options available |

| Fire Retardancy | Meets CFM, NFPA-701 standards |

👉 Get Your Factory-Direct Quote Now

Application Focus: Magnetic PVC Strip Curtains for Cold Storage

Nowhere is the value of a magnetic seal more apparent than in temperature-controlled environments.

👉 Get Your Factory-Direct Quote Now

Maintaining Critical Temperatures with Heavy Duty Magnetic Plastic Curtains for Freezer Doors

Magnetic PVC strip curtains for cold storage create an exceptionally tight thermal barrier. This seal is crucial for maintaining critical temperatures in coolers and freezers, ensuring food safety, pharmaceutical integrity, and process stability. The magnetic closure prevents the constant ingress of warm, moist air that plagues standard strip doors.

Preventing Ice Buildup and Reducing Defrost Cycles

Warm air infiltration is the primary cause of ice buildup on evaporator coils and freezer walls. By minimizing this, heavy-duty magnetic plastic curtains for freezer doors reduce the frequency and duration of costly defrost cycles. This not only saves energy but also decreases temperature fluctuations, protecting product quality.

👉 Get Your Factory-Direct Quote Now

Why Cold Storage Magnetic PVC Strip Barriers are Essential for Food Safety

Maintaining a consistent cold chain is non-negotiable in the food industry. Cold storage magnetic PVC strip barriers act as a critical control point, stabilizing temperatures and preventing the environmental fluctuations that can lead to bacterial growth and spoilage. Their hands-free operation also reduces cross-contamination from manual door handling.

Application Focus: Food Processing and Cleanroom Environments

In sterile and hygienic settings, controlling the environment is everything.

👉 Get Your Factory-Direct Quote Now

How Magnetic Vinyl Strip Doors for Cleanrooms Minimize Airborne Particulates

Magnetic vinyl strip doors for cleanrooms create a floor-to-ceiling seal that is highly effective at blocking the movement of dust, pollen, and other airborne particulates. The smooth, non-porous surface of the PVC is easy to clean and does not shed fibers, making it an ideal solution for maintaining ISO cleanroom standards. These industrial magnetic vinyl curtains for cleanrooms are a cost-effective alternative to more complex airlock systems.

Enhancing Hygiene Protocols with Hands-Free Passage

In food processing and cleanroom environments, minimizing contact with surfaces is a key hygiene principle. The self-closing, hands-free nature of magnetic curtains eliminates the need for personnel to touch door handles or push through strips with their hands, directly reducing the risk of cross-contamination. This makes magnetic PVC strip doors for food processing an essential component of any HACCP plan.

👉 Get Your Factory-Direct Quote Now

Using Magnetic Plastic Door Curtains for Pest Control and Dust Management

The tight seal provided by magnetic curtains forms a formidable barrier against insects, rodents, and other pests. This feature, combined with their ability to contain dust and debris within specific work zones, makes them an invaluable tool for maintaining facility-wide cleanliness and compliance.

Application Focus: Warehouses and High-Traffic Logistics Hubs

In the fast-paced world of logistics, workflow, safety, and durability are paramount.

👉 Get Your Factory-Direct Quote Now

Ensuring Safety with Transparent Magnetic PVC Strips for Factory Entrances

Visibility is a major safety concern in areas with forklift and pedestrian traffic. Transparent magnetic PVC strips for factory entrances provide a clear line of sight, allowing operators to see what—or who—is on the other side of the doorway before passing through. This dramatically reduces the risk of collisions and workplace accidents.

Why Durable Magnetic Plastic Strips are Crucial for High Traffic Doors (Forklifts & Personnel)

A durable magnetic PVC strip curtains warehouse solution is engineered to withstand constant, heavy use. The combination of thick-gauge PVC and a secure magnetic closure ensures the curtain can handle repeated impacts from forklifts, pallet jacks, and carts while reliably snapping back into place every time. This resilience is something standard, non-magnetic strips simply cannot match.

👉 Get Your Factory-Direct Quote Now

Streamlining Workflow with Self-Closing Magnetic PVC Strip Curtains in a Factory Setting

Time is money in a factory or warehouse. Self-closing magnetic PVC strip curtains in a factory eliminate the need for drivers to stop, dismount, and open a door. The hands-free passage allows for a continuous, uninterrupted flow of traffic, boosting productivity and reducing transit times between different zones.

Step-by-Step Installation Guide

Proper installation is key to maximizing the performance of your magnetic curtain. Most systems are designed for straightforward installation.

👉 Get Your Factory-Direct Quote Now

Pre-Installation Checklist: Measuring and Preparing Your Doorway

- Measure Accurately: Measure the height and width of the finished opening you intend to cover. For wall-mounted hardware, add several inches to the width and height to ensure a complete overlap.

- Inspect the Header: Ensure the area above the doorway where the hardware will be mounted is structurally sound, level, and free of obstructions like pipes or conduits.

- Choose Mount Type: Decide between a wall (face) mount above the opening or an in-jamb (header) mount inside the door frame. Wall mounting is most common as it provides a better seal.

Installing Your Magnetic PVC Strip Curtain with Mounting Hardware

- Secure the Mounting Bracket: Using the provided hardware, securely fasten the mounting rail to the wall or jamb. Use a level to ensure it is perfectly horizontal.

- Hang the Strips: Most systems use a simple hook-on or bolt-on design. Begin hanging the PVC strips one by one, starting from one side.

- Set the Overlap: Overlap each subsequent strip according to the manufacturer's recommendation (e.g., 2 holes for 50% overlap). Ensure the magnets align correctly and make contact along their entire length.

- Trim for Height (If Necessary): The strips should hang so they just touch or have a slight "break" on the floor for the best seal. Trim any excess length with a utility knife.

👉 Get Your Factory-Direct Quote Now

Tips for a Perfect Fit and Seal on Custom-Sized Doorways

For custom-sized magnetic PVC industrial curtains, precision is key. Always double-check your measurements before ordering. When installing, ensure the first and last strips extend slightly beyond the door frame to seal the corners effectively. Test the seal by observing how quickly the curtain closes and checking for any visible gaps.

Maintenance and Longevity: Protecting Your Investment

A heavy-duty magnetic PVC strip curtain is built to last, but simple maintenance will ensure it performs optimally for years.

👉 Get Your Factory-Direct Quote Now

A Simple Cleaning and Maintenance Schedule for Optimal Performance

- Weekly: Check for any debris caught between the magnetic edges that could prevent a full seal.

- Monthly: Clean the strips with a mild solution of soap and water. This maintains transparency for safety and removes grime that can degrade the PVC over time. Avoid harsh or abrasive chemical cleaners.

- Quarterly: Inspect the mounting hardware to ensure all bolts and fasteners are tight.

How to Inspect for Wear and Tear in Heavy-Duty Environments

Look for deep scratches that impair visibility, tears near the top of the strips where they hang, and any damage to the welded magnet pockets. Pay close attention to the bottom of the strips, which experience the most contact and wear.

👉 Get Your Factory-Direct Quote Now

Sourcing and Replacing Individual Strips to Extend Curtain Life

One of the major benefits of a strip curtain system is modularity. If a single strip becomes damaged, you do not need to replace the entire door. You can order individual replacement strips and easily swap them out, making repairs cost-effective and extending the overall life of your investment.

The Strategic Advantage of OEM and Bulk Procurement

For businesses with large-scale needs or multiple facilities, a strategic procurement approach offers significant advantages.

👉 Get Your Factory-Direct Quote Now

Why Factory-Direct Sourcing Delivers Superior Cost and Quality

Sourcing directly from an Original Equipment Manufacturer (OEM) cuts out intermediary markups, leading to substantial cost savings, especially on bulk orders. OEM suppliers also offer deeper product knowledge and can provide better support and customization options than a general reseller.

The Benefits of Custom Size Magnetic PVC Industrial Curtains for Unique Facilities

Off-the-shelf solutions don't fit every opening. An OEM partner can provide custom size magnetic PVC strip curtain solutions tailored to your exact specifications, whether for oversized conveyor openings, irregular doorways, or unique environmental challenges. This ensures a perfect fit and optimal performance.

👉 Get Your Factory-Direct Quote Now

Streamlining Procurement: Ensuring Consistency Across Multiple Sites

For national or global companies, partnering with a single OEM supplier ensures product consistency, quality, and pricing across all locations. This simplifies procurement, standardizes maintenance procedures, and guarantees that every facility benefits from the same high level of performance and safety.

Meeting Safety, Health, and Noise Compliance Standards

Industrial magnetic curtains also play a vital role in creating a safer and more compliant workplace.

👉 Get Your Factory-Direct Quote Now

Enhancing Visibility and Reducing Collision Risk in Busy Areas

The excellent optical clarity of transparent magnetic vinyl industrial curtains is a primary safety feature. It allows forklift operators and pedestrians to anticipate traffic, preventing costly and dangerous collisions in busy crossways.

The Role of Magnetic Curtains in Noise Reduction and Sound Insulation

The thick, dense PVC material and the complete seal of a magnetic curtain provide effective sound insulation. They can significantly reduce noise transmission between a loud production floor and quieter office or administrative areas, helping to meet OSHA noise exposure limits and creating a more comfortable work environment.

👉 Get Your Factory-Direct Quote Now

Adhering to OSHA and FDA Guidelines in Regulated Industries

In industries regulated by the FDA and OSHA, magnetic curtains help meet compliance requirements. They support HACCP plans by preventing contamination, enhance workplace safety by improving visibility, and help control environmental variables as mandated by various health and safety codes.

Comparative Analysis: Magnetic Curtains vs. Alternative Solutions

How do magnetic curtains stack up against other common doorway solutions?

👉 Get Your Factory-Direct Quote Now

Cost & Efficiency: Magnetic Strips vs. High-Speed Roll-Up Doors

- High-Speed Doors: Offer a superior seal but come at a much higher initial cost, require electricity to operate, and involve complex maintenance and repairs.

- Magnetic Curtains: Provide an excellent seal at a fraction of the cost. They require no power and maintenance is simple and inexpensive. For many applications, they offer 90% of the performance for 20% of the cost.

Performance Breakdown: Magnetic vs. Standard (Non-Magnetic) Hook-On Strips

As discussed, the difference is the seal. Standard strips inevitably gap, leak energy, and allow contaminants to pass. The self-closing magnetic PVC strip curtain provides a consistently superior barrier, making it a clear performance winner in any application where environmental separation is important.

👉 Get Your Factory-Direct Quote Now

When to Choose Magnetic Curtains Over Air Curtains for Climate Control

- Air Curtains: Use a high-velocity stream of air to create a barrier. They are effective but consume a significant amount of electricity and can be noisy. They are also ineffective against physical contaminants like pests or heavy dust.

- Magnetic Curtains: Provide a physical barrier that stops air, pests, dust, and noise. They consume no energy to operate. For most industrial separation needs, a magnetic curtain is the more energy-efficient and comprehensive solution.

Frequently Asked Questions & Your Next Steps

👉 Get Your Factory-Direct Quote Now

Answering Top Questions About Industrial Magnetic Curtains

- What are magnetic PVC strip curtains?

They are industrial door barriers made of overlapping PVC strips with magnets embedded in the edges, creating a self-closing, hands-free seal. - What are the main benefits of using magnetic PVC strip curtains in a warehouse?

The top benefits are significant energy savings, improved temperature control, dust and pest reduction, enhanced safety through visibility, and increased workflow efficiency. - How do magnetic PVC strip curtains work to save energy and maintain temperature?

The magnetic seal eliminates gaps between strips, preventing the leakage of heated or cooled air and drastically reducing the load on HVAC systems. - What is the difference between magnetic and standard (non-magnetic) PVC strip curtains?

Magnetic curtains use magnets to actively pull the strips together for a complete seal. Standard curtains rely only on gravity and often have gaps. - How effective are magnetic PVC strip curtains at preventing dust, insects, and other contaminants?

They are highly effective. The gap-free physical seal provides a robust barrier against airborne particulates and pests. - What are the common applications for magnetic PVC strip curtains in industrial settings?

Common applications include warehouse loading docks, freezer and cooler doorways, cleanrooms, food processing areas, paint booths, and as dividers within a factory. - Are magnetic PVC strip curtains easy to install and maintain?

Yes, they are designed for simple installation with basic tools. Maintenance typically involves regular cleaning and periodic inspection for damage. - What is the typical installation process for magnetic PVC strip curtains?

The process involves measuring the doorway, mounting the hardware track above the opening, and then hanging the individual strips onto the track with the correct overlap. - What maintenance is required to ensure the longevity of magnetic PVC strip curtains?

Regular cleaning with mild soap and water, checking that the hardware remains tight, and promptly replacing any torn or heavily damaged strips. - What thickness and type of PVC strip is most suitable for heavy industrial use?

For heavy forklift traffic, a thicker strip (.120" or .160") and a higher overlap percentage (67% or 100%) are recommended for maximum durability. - What are the temperature ratings for magnetic PVC strip curtains, especially for cold storage or freezer applications?

Standard PVC is rated down to 0°F (-18°C). For freezers, you must use Low-Temp or Polar grade PVC, which is rated for temperatures as low as -40°F/C. - Do magnetic PVC strip curtains provide effective sound insulation or noise reduction?

Yes, the dense PVC material and tight seal provide a noticeable reduction in noise transmission between different areas. - How do magnetic strip curtains improve hygiene in environments like food processing or clean rooms?

They provide hands-free passage, reducing cross-contamination, and create a physical barrier against airborne contaminants and pests. - Are magnetic PVC strip curtains suitable for high-traffic areas with forklifts and personnel?

Absolutely. Durable magnetic plastic strips for high traffic doors are specifically designed to withstand impacts from machinery and heavy use. - Do magnetic PVC curtains allow for hands-free passage?

Yes, this is one of their primary advantages. The magnetic seal releases with a gentle push and closes automatically. - How durable are magnetic PVC strip curtains for heavy industrial use?

When the appropriate thickness and material grade are chosen, they are extremely durable and designed for the rigors of an industrial environment. - Can magnetic PVC strip curtains be customized to fit different door sizes?

Yes, OEM suppliers specialize in creating custom size magnetic PVC industrial curtains to fit virtually any opening perfectly. - What materials are magnetic PVC strip curtains typically made from?

They are made from high-quality flexible Polyvinyl Chloride (PVC), with industrial-grade magnets sealed into the edges and mounting hardware made of galvanized or stainless steel. - Do magnetic PVC strip curtains offer good visibility for warehouse operations?

Yes, the standard clear PVC offers excellent optical clarity, which is a key safety feature in busy environments. - Where can I buy heavy-duty magnetic PVC strip curtains for a warehouse?

For the best quality, customization, and price, it is recommended to source them directly from a specialized OEM manufacturer.

👉 Get Your Factory-Direct Quote Now

Summary of Key Benefits for Your Business

- Cost Reduction: Slash energy bills and reduce product spoilage.

- Increased Productivity: Streamline workflow with hands-free, uninterrupted traffic flow.

- Enhanced Safety & Compliance: Improve visibility to prevent accidents and create a physical barrier that aids in meeting health and hygiene standards.

- Environmental Control: Effectively manage temperature, dust, noise, and pests.

👉 Get Your Factory-Direct Quote Now

How to Request a Custom Quote for Your Facility's Needs

Ready to unlock these benefits for your operation? The next step is to partner with an expert who can assess your unique requirements and provide a solution tailored to your facility.

Contact our team today to discuss your application. We provide factory-direct pricing, full customization on all industrial magnetic plastic door curtains, and expert guidance to ensure you receive the perfect solution for your business. Provide us with your door dimensions and operating environment, and we will deliver a comprehensive, no-obligation quote.